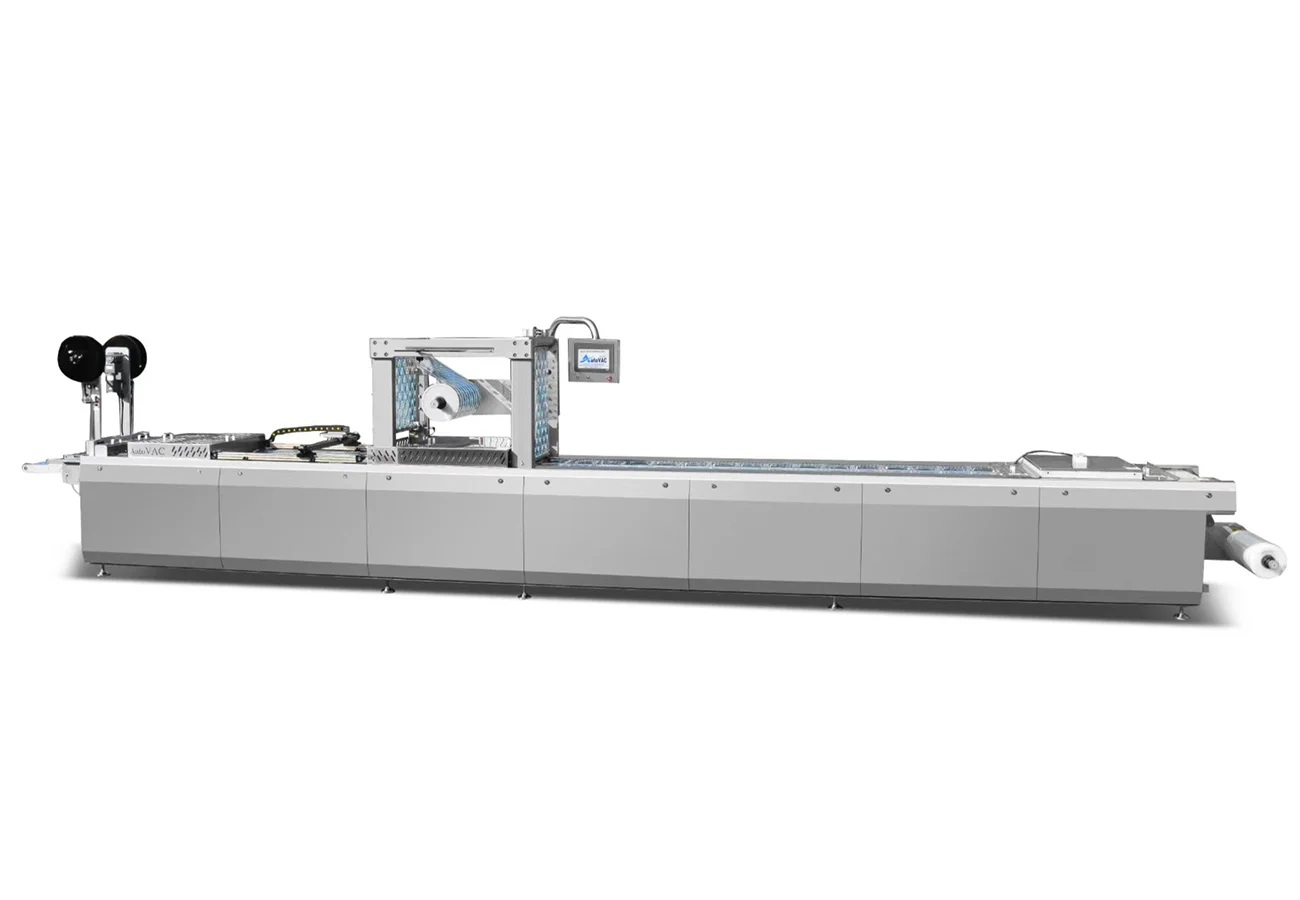

DLZ-2023 — Fully Automatic Stretch Film Vacuum Packaging Machine

The 2023 new model fully automatic stretch film vacuum packaging machine delivers advanced thermoforming technology, offering hygienic, efficient, and cost-effective packaging for a wide range of products.

The 2023 New Model Fully Automatic Stretch Film Vacuum Packaging Machine — also known as a thermoforming vacuum packaging machine or automatic plastic tray forming vacuum packer — integrates forming, loading, vacuuming, and sealing in one system.

The process involves heating the film, forming it into container shapes using precision molds, placing products into the formed cavities, and applying vacuum sealing. The deep-draw film used in this system is available in both soft and rigid types, featuring excellent formability, high transparency, oxygen barrier, heat resistance, sealing strength, anti-fog properties, and easy opening.

This machine is capable of packaging solids, liquids, soft materials, and fragile products, while also supporting vacuum flexible packaging, rigid film MAP packaging, and blister packaging. It offers hygienic operation, reduced labor demand, and lower overall costs.

Scope of Application:

Frozen and chilled meat portions

Meat products

Soybean products

Seafood

Snack foods

Medical products & devices

Electronic components

Hardware tools

This model represents the future trend in vacuum and MAP food packaging technology.

DLZ-2023 — Fully Automatic Stretch Film Vacuum Packaging Machine (New Model)

| Item | Specification |

|---|---|

| Model | DLZ-2023 — PrimePack-VDF-520-120-SR-2023 |

| Machine Type | Fully Automatic Stretch Film Vacuum Packaging Machine (Thermoforming Type) |

| Film Type | Deep-draw film (soft & rigid options); high transparency, oxygen barrier, anti-fog, heat-resistant |

| Packaging Options | Vacuum packaging, MAP packaging (rigid film with gas flushing), blister packaging |

| Forming Process | Film heating and thermoforming molds to create cavities; hygienic and efficient operation |

| Applications | Meat, seafood, tofu/soy products, snack foods, medical products, electronics, hardware |

| Advantages | Reduced labor, hygienic, cost-efficient, supports flexible and rigid film packaging |