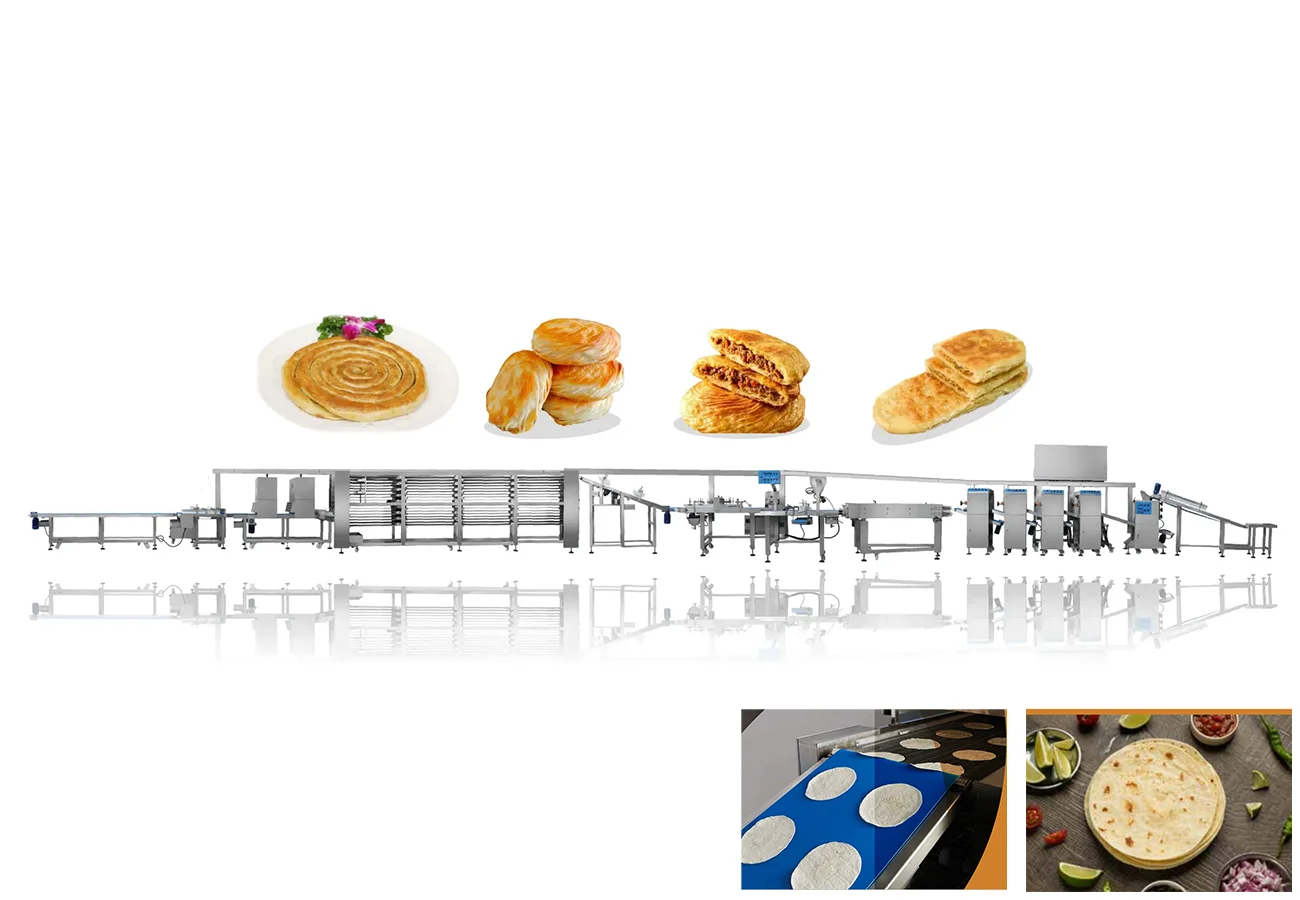

Automatic Pastry Processing Line (Tortilla / Flatbread Production)

Integrated pastry production line for tortillas and flatbreads, with hydraulic pressing, tunnel oven, and smart automation.

The Automatic Pastry Processing Line offers a one-stop solution for manufacturing tortillas and other flatbread-style products.

From dough sieving, pressing, heating, baking, to packaging, the system is designed to be adaptable and optimized according to your factory layout, production capacity, and labor availability.

Engineered with ANKO’s custom solutions, this line ensures high-efficiency production, consistent quality, and workplace safety.

Key components and features:

-

Hydraulic Pressing & Heating System

Uniformly presses dough regardless of shape or hardness. -

Safety Interlock Mechanism

Automatically halts pressing and heating when the guard is opened. -

Three-Layer Tunnel Oven

Features 8 independently controlled burners with adjustable top/bottom heat and automatic temperature regulation via sensors. -

High-Productivity Output

Capable of pressing 4 pieces (8 to 10 inches) simultaneously with an average capacity of 1 piece per second.

This production line is ideal for industrial-scale production of tortillas, wraps, chapati, roti, and similar baked goods.

Automatic Pastry Processing Line

| Item | Specification |

|---|---|

| Process Flow | Sieving → Dough pressing & heating → Baking → Packaging |

| Pressing System | Hydraulic, presses 4 pcs (8–10 in) per cycle |

| Output Capacity | 1 piece per second |

| Oven Type | Three-layer tunnel oven with 8 burners |

| Temperature Control | Independent top/bottom heat with auto-regulating sensors |

| Safety Features | Interlock system stops machine when opened |

| Application | Tortilla, flatbread, roti, chapati, wraps |